Riser System Design

Vibro-Acoustics’ floating riser solutions are designed to address thermal growth and vibration issues for vertical piping systems in a building.

Pipe Risers undergo changes in temperature as chilled or heated water enters the pipe. As the temperature changes, the pipe expands or contracts. If the piping system is anchored to the structure, the thermal growth or shrinkage will apply stress on the pipe riser support points, potentially damaging the building structure and pipe. It is also important to isolate the pipe from the building structure in order to eliminate unwanted noise and vibration paths. If required, seismic considerations need to be taken into account to ensure the piping system can withstand a seismic event.

Vibro-Acoustics is an expert in designing thermal and seismic solutions for vertical piping systems. Our spring riser supports provide complete noise and vibration control and are designed to allow controlled expansion and contraction of pipe risers. Floating riser solutions fully isolate the piping system from the structure with the use of spring isolators, eliminating high pipe anchor loads at the floor supports. Vibro-Acoustics will also specify the final load at the structure during the submittal phase for each floor mount. For seismic applications, we will consider lateral seismic loads in the design of the floating riser system to achieve optimal performance.

Why is it needed?

In tall buildings, pipe risers may expand and contract up to 2” or more. This induces stress and can cause buckling, breaking and connection failures in riser piping if not addressed.

Where is it needed?

Expansion loops or compensators are used to introduce a “break” in the piping at strategic places. This requires pipe anchors and guides to direct the thermal movement toward the expansion compensator or loop.

How do they work?

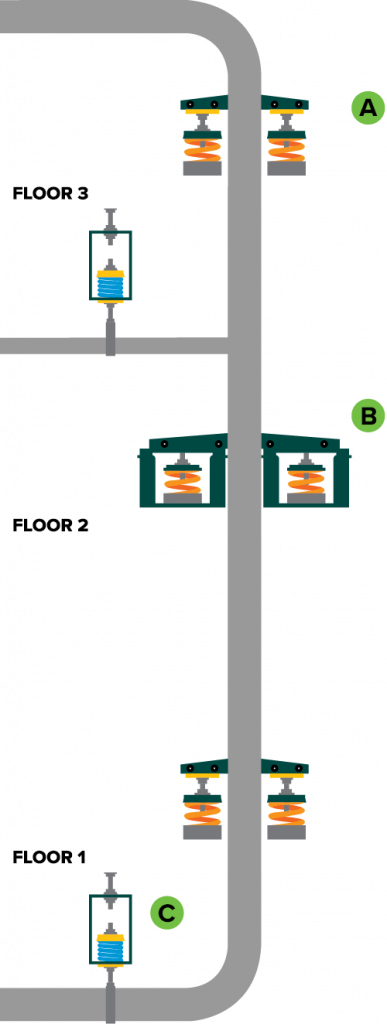

- Piping is supported on every other floor

- The floating pipe riser system is designed by experts to eliminate pipe stress due to thermal expansion

- The center of the riser is supported on stiffer isolators, directing the thermal expansion towards the upper and lower extremes of the system where the piping is supported on softer springs

- No pipe anchor is needed

- For seismic applications, the system can still float with additional attention given to restraining the pipe against seismic accelerations while allowing the pipe to float against thermal movement

Our competitive advantages

- The only true vibration-free installation method (good for hotels, condos and lightweight modern structures).

- No maintenance required.

- No potential leaks, no potential mold issues.

- Reduced costs – no anchor, no guides, no expensive thermal compensators.

- No piping anchor and so no extra structural attention or re-design of the floor.

- Space savings – no expansion loop required.

Submittal

We design the whole system as specified whether it’s a floating, traditional or hybrid system. We are involved in the approval process and consider site feedback and engineer of record’s comments.

Product

We provide all spring supports for the floating riser system. We have standard FST isolators but can also customize a solution for very tall risers if needed

Site Visit

We help our customers get the installation right. We support contractors and consultants from the approval stage all the way down to the final installation stage with kick-off meetings, phone conferences and site visits where we take measurements and inspect installation.