BC

BulletClampTM

The Challenge

ONCE BUILT, the steel structure of a building is usually off-limits to welding or drilling for the purposes of attaching brackets and fasteners. In typical seismic restraint design, the attachments to structure are determined well after the steel structure has been erected, eliminating the opportunity to coordinate their locations. Securing non-structural components with seismic restraints in a building with a steel structure can therefore be quite challenging.

The Risk

INSTALLING A STANDARD BEAM CLAMP may seem like the best solution for structural attachment of seismic restraints for non-structural components to steel structures like this. However, additional design modifications are typically required for standard beam clamps to make them “seismic”.

Most seismically rated beam clamps in the market are large, bulky, difficult to handle and labor intensive.

The Solution

The fastest-to-install, compact, tough, and seismically-rated beam clamp

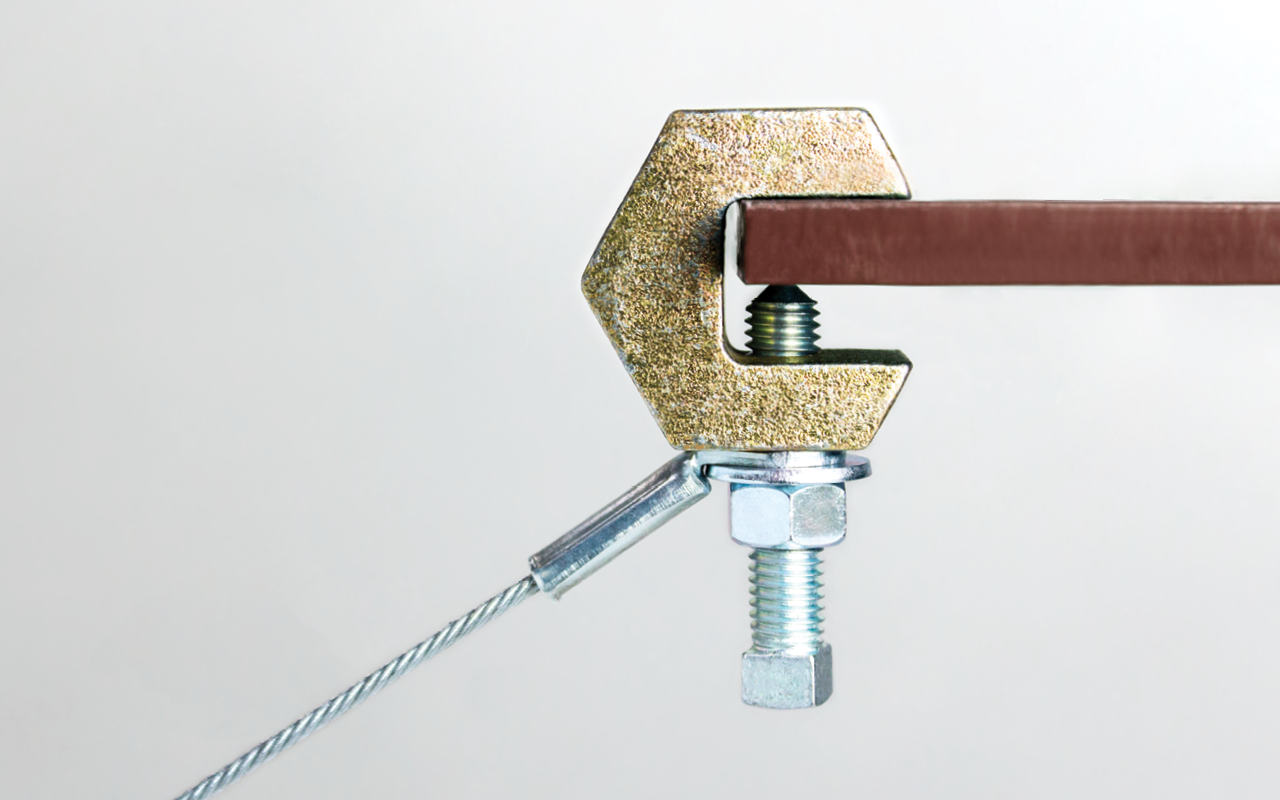

With BulletClampTM and its unique and simple design (patent pending), Vibro-Acoustics offers contractors a fast and easy-to-install method of attaching seismic restraints to structural steel.

LABOR SAVINGS

Quick installation:

Simply fasten the set screw to secure the clamp to structure and the restraint to the clamp, and save significant installation, adjustment, labor, and material costs. Other products available in the market require multiple installation operations to achieve similar seismic ratings.

One size fits all:

The BulletClampTM is fully compatible with all sizes of BulletBraceTM and RRK rigid restraint kits. This takes away coordination and planning hassles from installer.

Stock-friendly:

Beam clamps are necessary on many projects requiring seismic restraints attached to steel structure where welding or drilling is not allowed.

Engineered to perfection:

BulletClampTM has been through vigorous testing with applied loads at many angles, corresponding to our V-Anchor Design methodology. Restraints can be attached to the BulletClampTM towards or away from the connection. The ductile cast iron frame with its protective zinc-chromate finish is durable, impact resistant, and corrosion resistant.

QUANTIFIED SAVINGS

4 min savings per clamp

*Compared to standard products

- Installing BulletClamp

- Installing similar products by others

COMMERCIALLY AVAILABLE SEISMIC BEAM CLAMPS OF SIMILAR PERFORMANCE require multiple cone point set screws with retainers or additional bolts to attach a restraint bracket. BulletClampTM utilizes one set screw for both the structural attachment and the restraint connection, resulting in at least two to three times less installation time. The ease of handling and installation only improves these odds. This can lead to over six hours of labor savings for every one hundred seismic restraint kits attached to steel.

Approximately

time savings

INSTALLATION

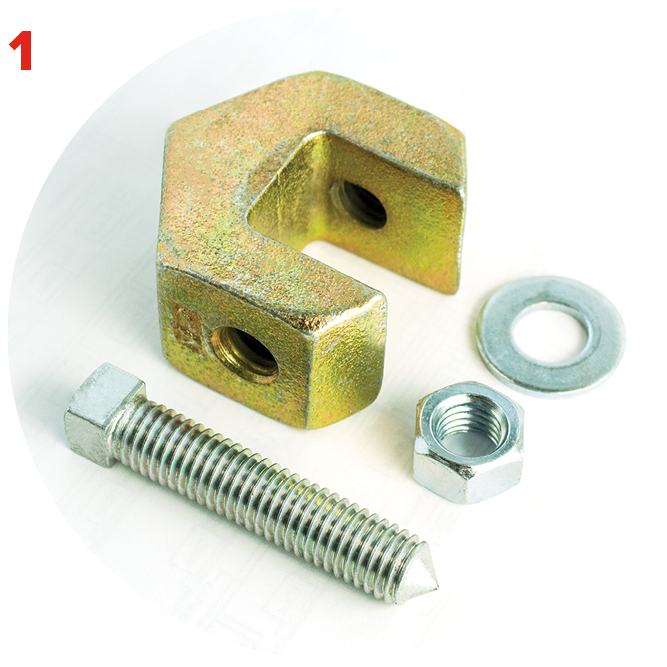

BC-50 is delivered in a package ready for installation.

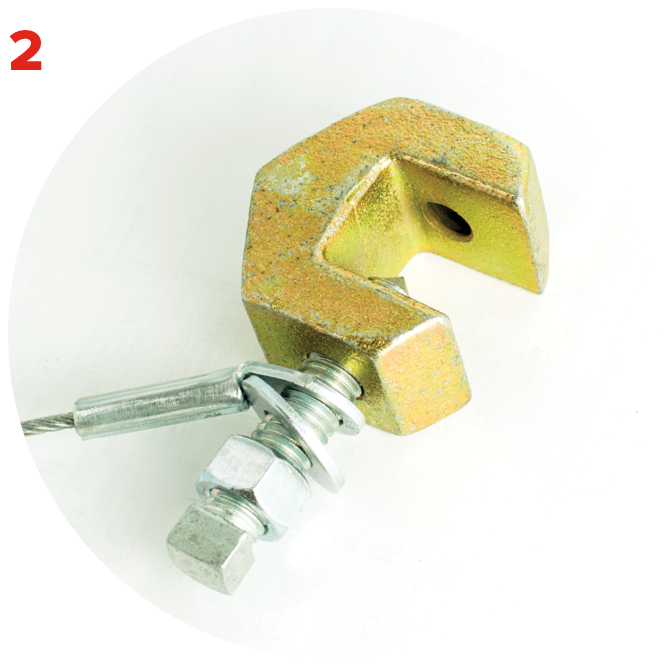

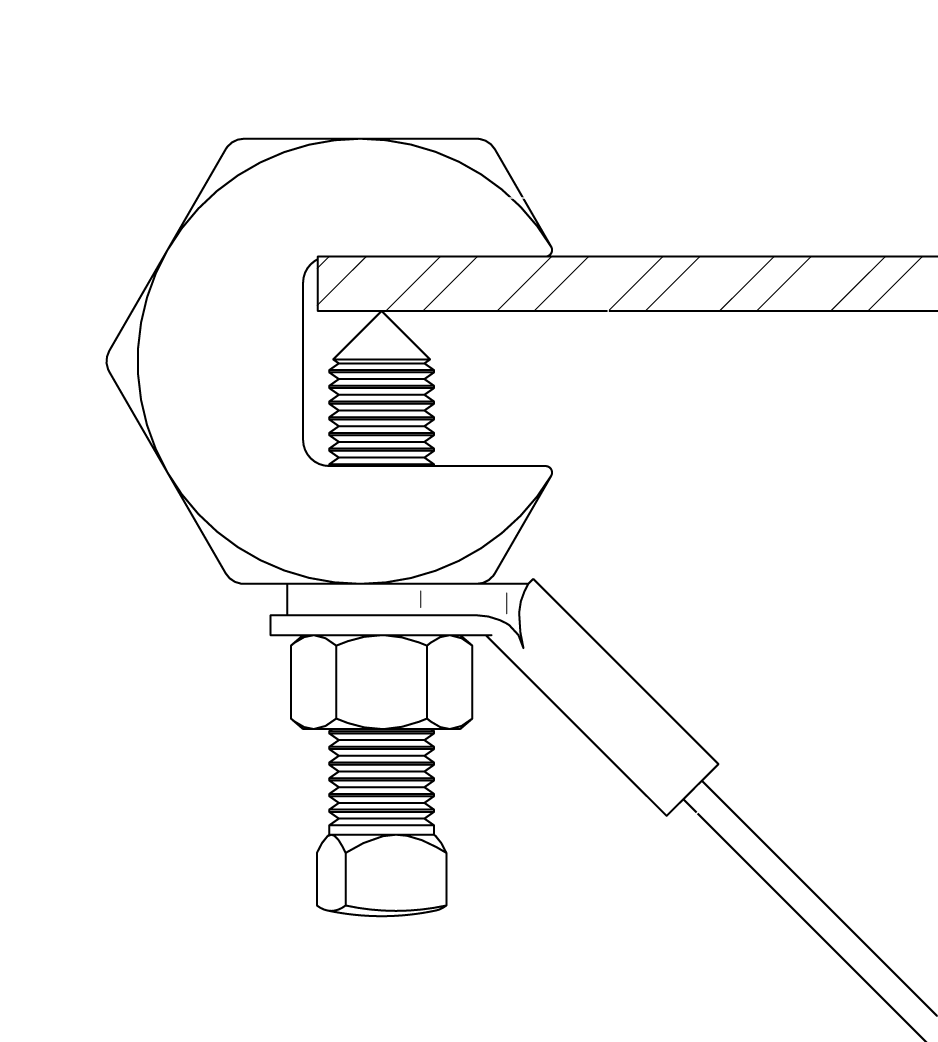

Put together hardware, and slide on the restraint bracket or stake eye as shown.

Apply 25 lbf∙ft (34 N∙m) of torque using a torque wrench or rotate the bolt one full turn after tightening by hand.

Hand tighten the hex nut to keep the restraint in place, and give an extra 1/6 of a turn to finish installation.

COMPACT AND STRONG

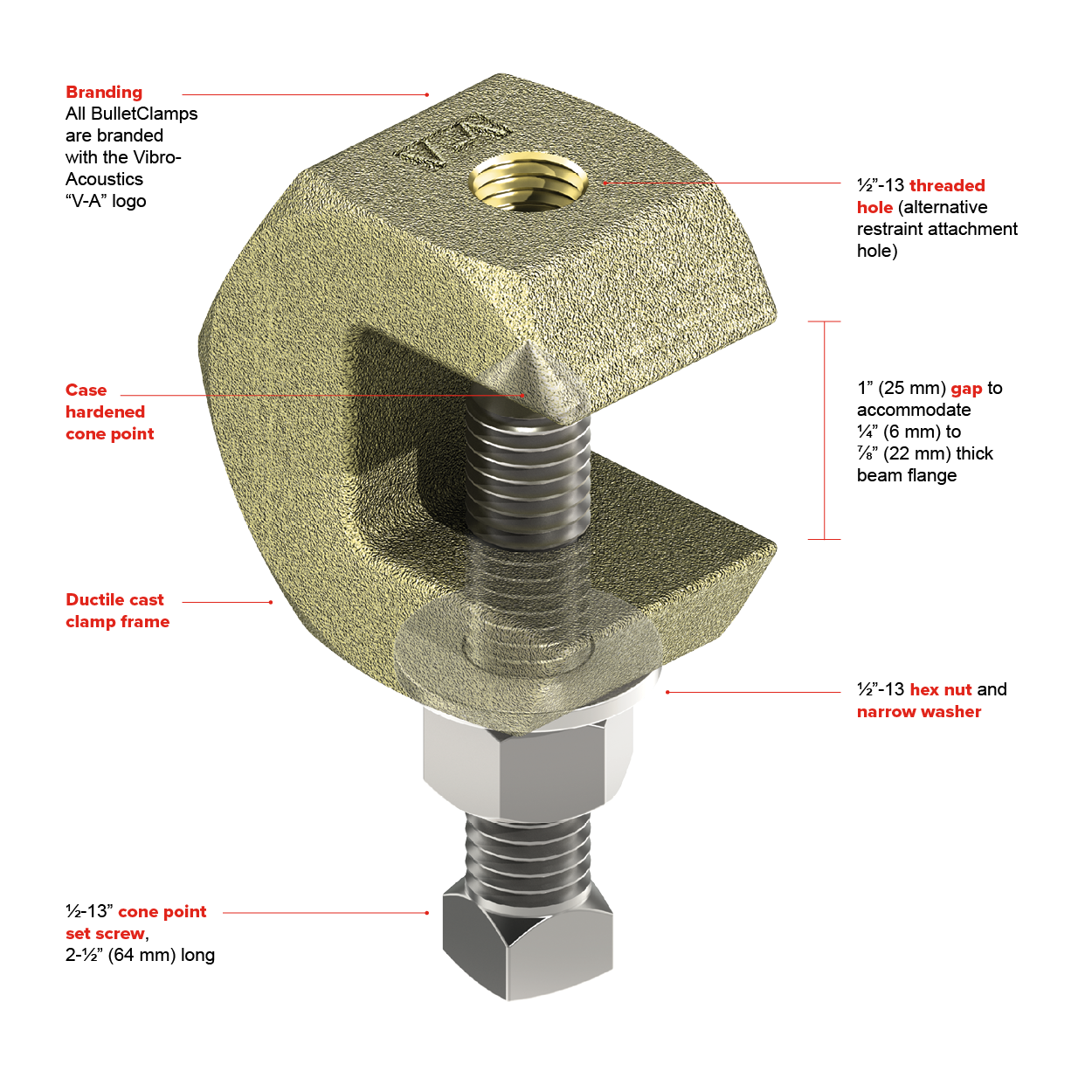

BulletClamp’s (patent pending) robust construction allows the special, case-hardened set screw to be a multi-functioning component — it serves as a clamp and restraint bracket attachment bolt. This novel product allows seismic sway bracing to be attached to steel structures without the need for additional parts, welding, or holes drilled into structure.

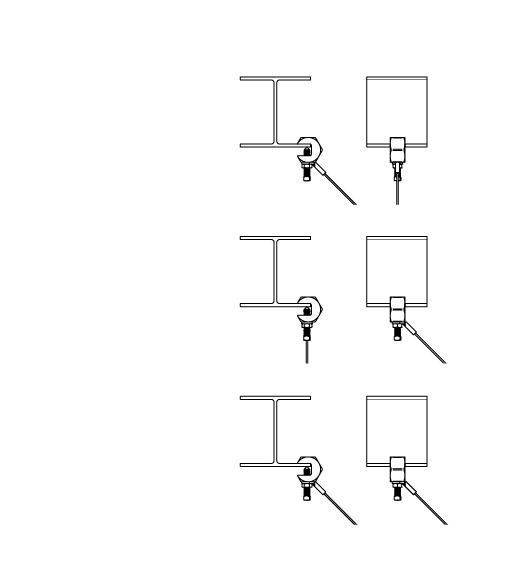

SEISMICALLY RATED APPLICATIONS

BulletClampTM enables cable and/or rigid restraint attachment to steel structures such as beams, girders, or steel joists.

KEEPING IT SIMPLE

Other products available in the market require multiple installation operations to achieve similar high seismic load ratings whereas BulletClampTM is far simpler to install.

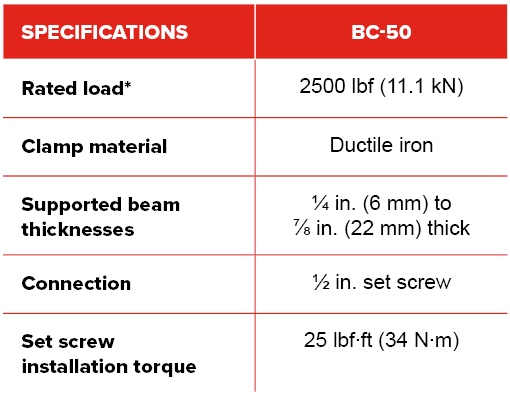

TECHNICAL SPECS

BulletClampTM BC-50 – Seismically rated beam clamps for attachment of seismic cable restraints and rigid restraints to structural steel without drilling the structure.

Beam clamp shall be constructed of a ductile cast frame, case hardened cone point set screw, and related hardware. Clamp frame shall be zinc-plated with supplemental yellow chromate treatment, and hardware and set screw shall be zinc-plated for corrosion protection. Clamp design shall allow installation of the restraint bracket to the clamp and the clamp to structure with a single attachment point. Published seismic beam clamp capacities at specified angles shall be established through testing. Test reports will be available from the manufacturer upon request.

*Rated load is maximum allowable restraint load installed at angles between 30° to 60° in two planes. The rating is based on testing under a wide range of installation variations.