COOLING TOWER SOLUTIONS

Single Source Responsibility Support Solution

HAVE YOU CONSIDERED?

COOLING TOWER INSTALLATION PROBLEMS REQUIRING ENGINEERING SOLUTIONS

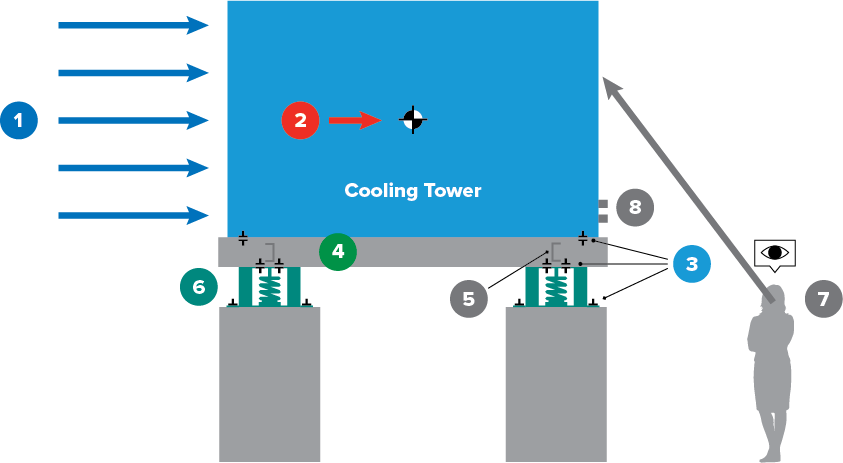

1 Wind Forces

As defined by IBC, ASCE and other codes for all outdoor equipment.

2 Seismic Forces

As defined by IBC, ASCE and other codes for non-structural components that require seismic restraint.

3 Anchoring Attachment

Nonstructural components and their supports shall be attached (or anchored) to the building structure or ground to withstand horizontal and vertical forces (wind/seismic) through positive attachment in a continuous load path.

4 Support Base

A cooling tower typically needs a structural steel base engineered to support its weight and overturning forces and to match tower support requirements, including mounting holes and maximum beam deflection between isolators.

5 Cross-bracing

Steel support bases require cross members that stiffen and stabilize point-loaded support base beams against seismic and wind forces. Bracing needs to be located to avoid interference with piping connections to bottom of tower.

6 Vibration Isolation

As required by contract documents to reduce vibration transmission to the building structure, and to provide restraint against wind and seismic forces.

7 Architectural Line of Sight

The lowest possible height is often desired by the building owner and architect. This problem requires special attention, especially for tower replacement projects.

8 Retrofit Height Requirements

Typical retrofits require matching and aligning with existing piping and supports.

SINGLE SOURCE RESPONSIBILITY FOR A TURNKEY COOLING TOWER SUPPORT SOLUTION.

Let Vibro-Acoustics assume the risk and liability for code-compliant supports

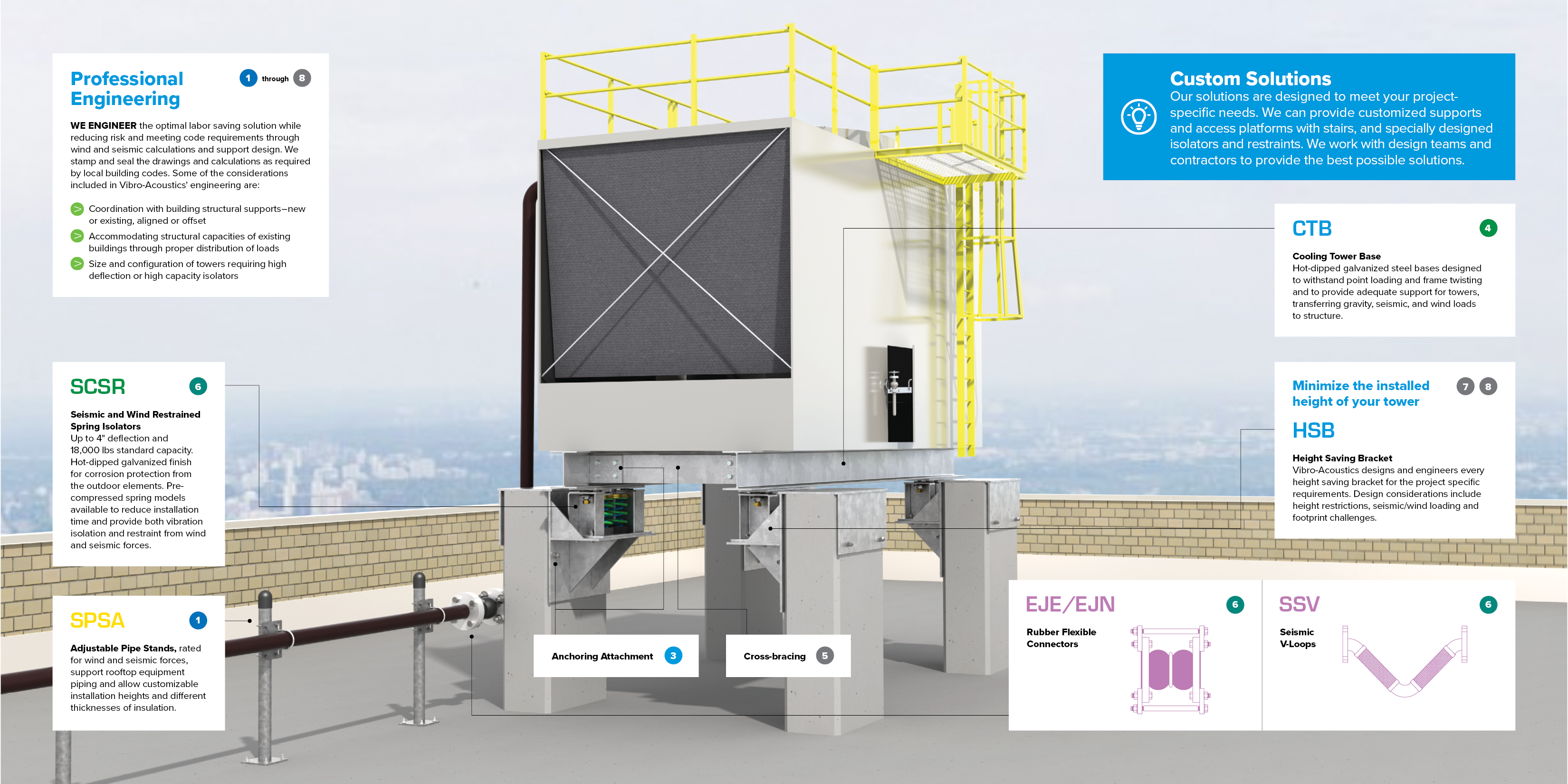

Vibro-Acoustics’ complete cooling tower support solution is designed to integrate with any new or retrofit cooling tower installation seamlessly. From piping support, vibration isolation for both the cooling tower and associated piping, to a base and structural support (including dunnage), and anchorage and attachments, the solution will help solve wind and seismic loads, vibration isolation and any associated structure-borne noise, and cooling tower integration challenges.

LABOR SAVINGS

Bolted design:

Supplied Knocked-Down with minimal site welding requirements. Large bases can be designed with bolted splice plates to allow lower cost shipping and handling. Fully factory-assembled bases available to minimize site time.

Risk reduction:

We reduce project risk by providing single-source responsibility for support, isolation, and restraint. Professional Engineer stamped submittals provide drawings, calculations, and installation instructions.

Tower replacement projects:

Retrofit projects are our specialty. We design and build ready-to-install solutions that incorporate height saving brackets, proper load distribution placement, and custom isolator housing designs to match existing structure and related challenges. This time and labor saving approach can eliminate the need to remove or rework existing supports, dunnage, and other rooftop equipment and structures.

Pre-compressed springs:

Our pre-compressed isolators can save contractors up to 35% in installation time compared to competitors’ products.

QUANTIFIED SAVINGS

CTB

Buy vs. Build Average

20-40 hrs

With Height-saving Brackets

+6-10 hrs

*Depending on size of cooling tower base

SPSA-4A

Buy vs. Build

1 hr

*Compared to building on-site

*Will be less if contractor has a pre-fabrication shop

SCSR-4A

Per isolator

20 min

*As compared with competitors’ products