NP

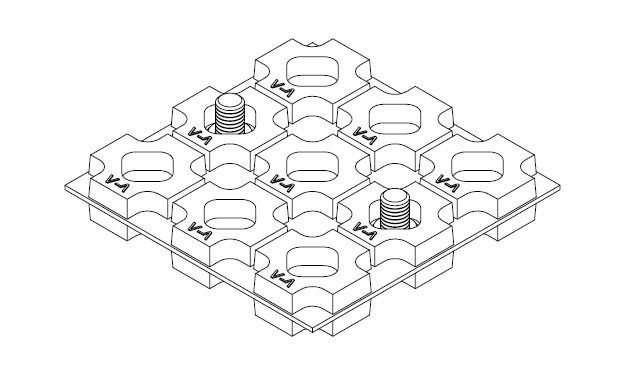

Neo+ Isolation Pad

The Challenge

MANY COMMONLY AVAILABLE PAD ISOLATORS are difficult to cut or modify on site due to installation restrictions and material thickness. Furthermore, seismic and wind restraint designs require equipment to be bolted down — oftentimes through pad isolators— leading to risks of short-circuiting the isolation or overloading the pads.

The Risk

WHEN A HOLE IS MADE in an isolation pad, it removes a certain area from the pad. This, in turn, results in reduced capacity for a given pad size. The issue could be resolved by engineering the pad selection, however, this is rarely done.

The Solution

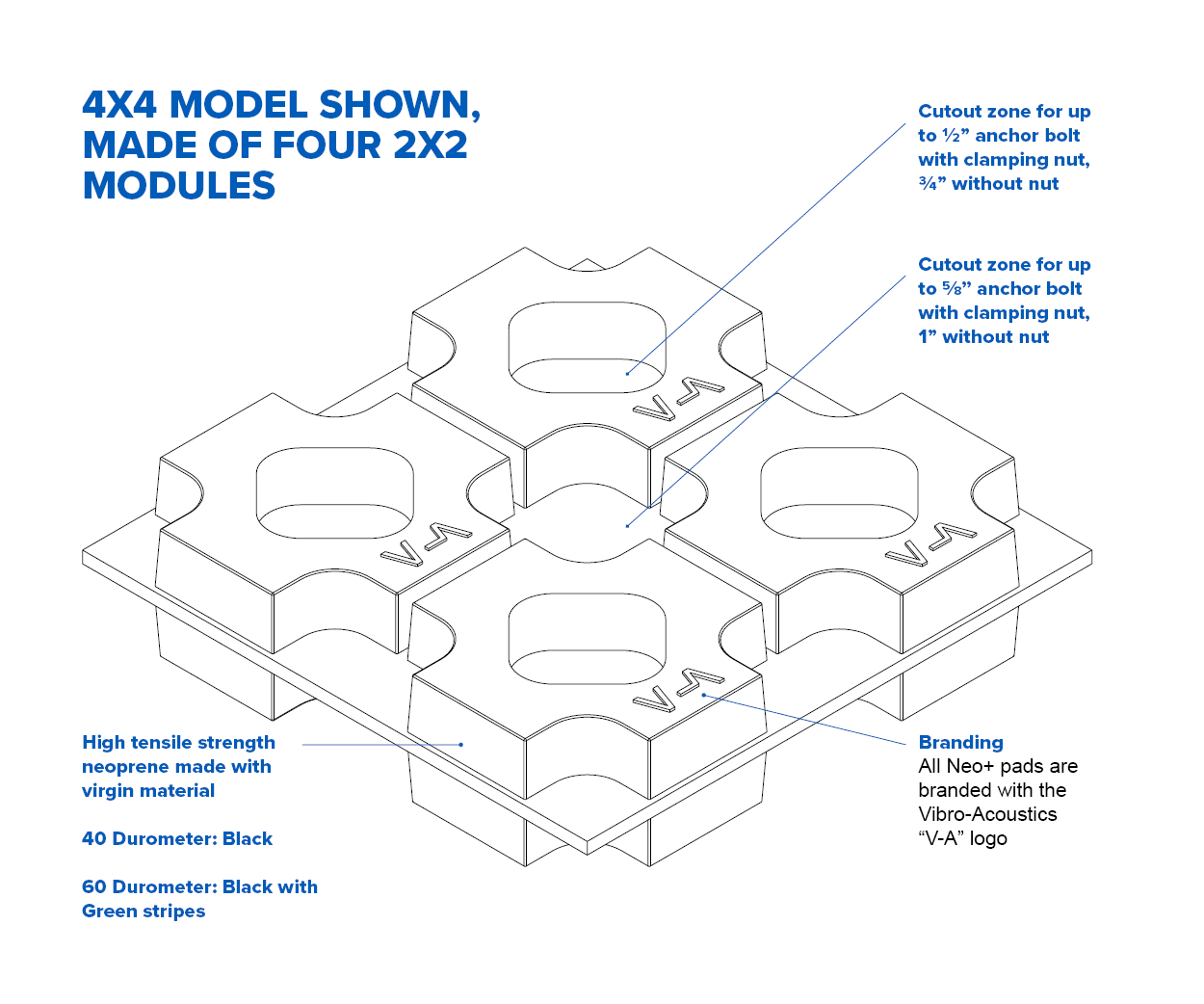

Neo+ isolation pads are designed to perform as published even when mounting anchor bolts are installed through the pads thanks to unique geometry, high strength compound and high shape factor.

LABOR SAVINGS

Accommodating shape:

Designed to fit most common anchor bolt sizes at the center and corners of the pad without having to make a hole through the thickest part of the pad.

Install anchors quickly:

Anchor mounting can be done quickly by simply cutting away or scoring a thin connective diaphragm.

Modular design:

Design can be cut to size in seconds to adjust for actual equipment weight and size.

Wider operating range:

Spend less time on troubleshooting. High strength material, 7/8-inch thickness in 40 and 60 Shore A Durometer selections and high

shape factor of 0.22 allows a very wide operating range, providing vibration control for any floor-mounted equipment.

Commercially available seismic beam clamps of similar performance require multiple cone point set screws with retainers or additional bolts to attach a restraint bracket. BulletClampTM utilizes one set screw for both the structural attachment and the restraint connection, resulting in at least two to three times less installation time. The ease of handling and installation only improves these odds. This can lead to over six hours of labor savings for every one hundred seismic restraint kits attached to steel.

INSTALLATION

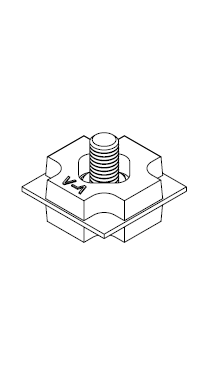

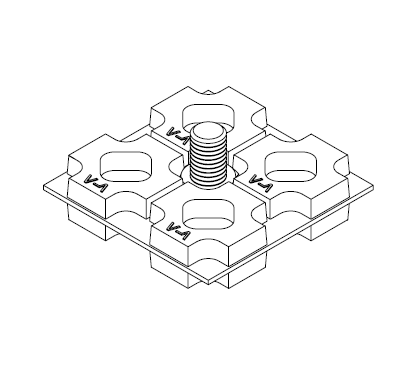

Score the designated anchor area in an “X” pattern using a knife.

Install the anchor per anchor manufacturer’s instructions, and push the pad over the installed anchor. The opening is designed to accommodate the size of the clamping hex nut required with concrete expansion anchors without interference.

Place the equipment on the pad and install the securing jam nuts on top of a neoprene grommet.

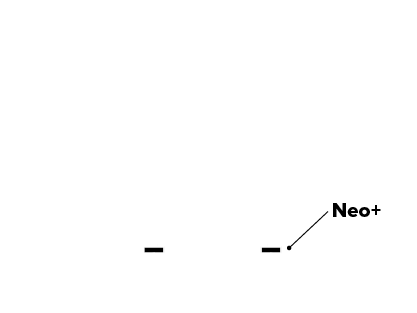

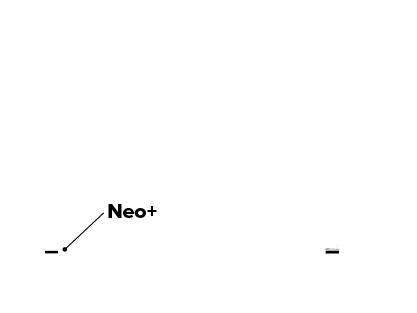

Up to ½″ anchor through center hole

Up to ⅝″ anchor through combined opening at 2×2 module corners

Use of multiple anchors on a single large pad at various locations

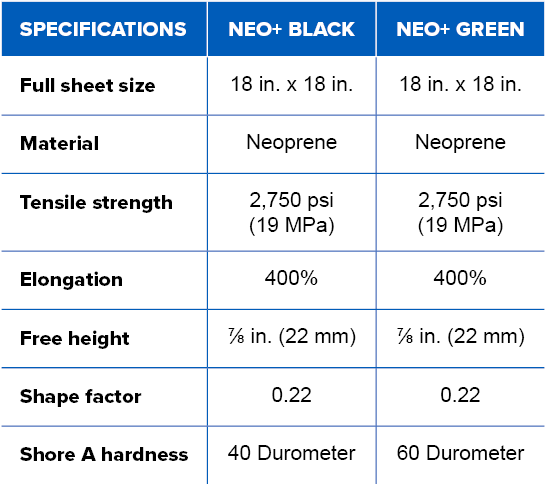

TECHNICAL SPECS

Type NP – Neo+TM Neoprene pad type isolators, ⅞” (22 mm) minimum thickness molded from high strength neoprene compound at minimum 2,750 psi (19 MPa) tensile strength.

PADS SHALL BE COLOR CODED for capacity, and sized to deflect 20% of the overall height at 0.18” (4.5 mm). Maximum allowable deflection is 25% of the overall height at 0.22” (5.5 mm). Pads shall allow for up to 5/8” hex head nuts or anchor bolts when anchored through with a clamping nut and up to 1” anchor bolts when anchored through without a clamping nut, without having to make holes that alter published load vs. deflection performance.

APPLICATIONS

AIR HANDLING UNITS

TRANSFORMER

INLINE PUMP

AIR COMPRESSOR

CHILLER