BB/ BBR

BulletBraceTM

The Challenge

IN SEISMIC APPLICATIONS, cable restraint systems provide the most common solution for restraining suspended components.

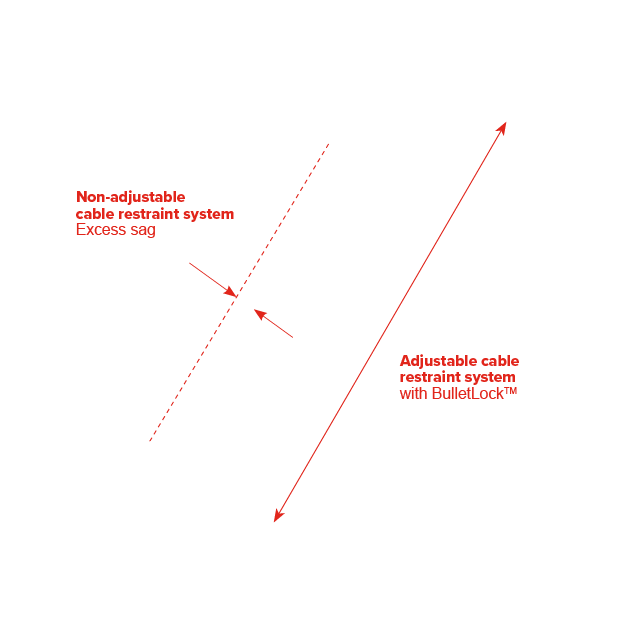

Cable restraints are either adjustable or non-adjustable. Adjustable cable restraints allow the installer to correct cable tension problems without having to replace or splice installed cable restraints. This saves installers from unnecessary rework time and cost.

Installing cable restraints can be a physically grueling exercise. They often need to be installed in hard-to-reach locations. The challenge is compounded when using non-adjustable restraint systems that use compression sleeves which require considerable effort and a large amount of space to operate the crimping tool.

The Risk

ALTHOUGH there are other adjustable restraint systems available, many are large, complicated or come unassembled, requiring significant time and effort to install. Any bracing system that is difficult to install could jeopardize the project schedule with longer installation times and higher installation costs.

The Solution

The fastest adjustable cable restraint system

With BulletBraceTM and its patented BulletLockTM mechanism (US Patent #9,625,003), Vibro-Acoustics offers contractors a cable restraint system that is fast and easy to use, minimizing installation time, effort and cost.

LABOR SAVINGS

Pre-Assembled:

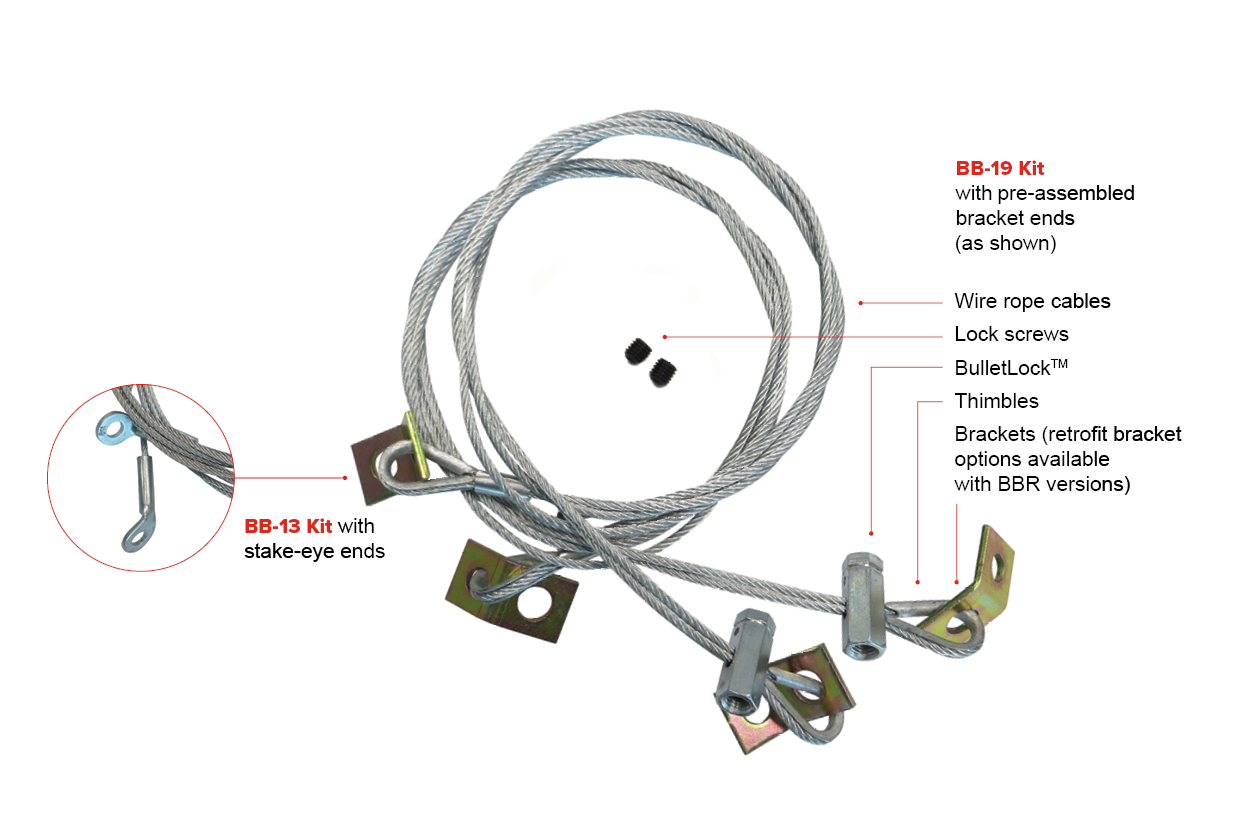

BulletBraceTM kits are shipped pre-assembled, a unique feature in today’s market, making them the fastest restraints to install.

Fewer restraints:

Combined with the V-Anchor engineering method, BulletBraceTM restraint kits allow for designs with fewer restraint points.

Lower risk and higher accuracy on attachments to building structures:

Our engineered attachment details will show attachment alternatives to help contractors make substitution decisions on-site.

Cost savings:

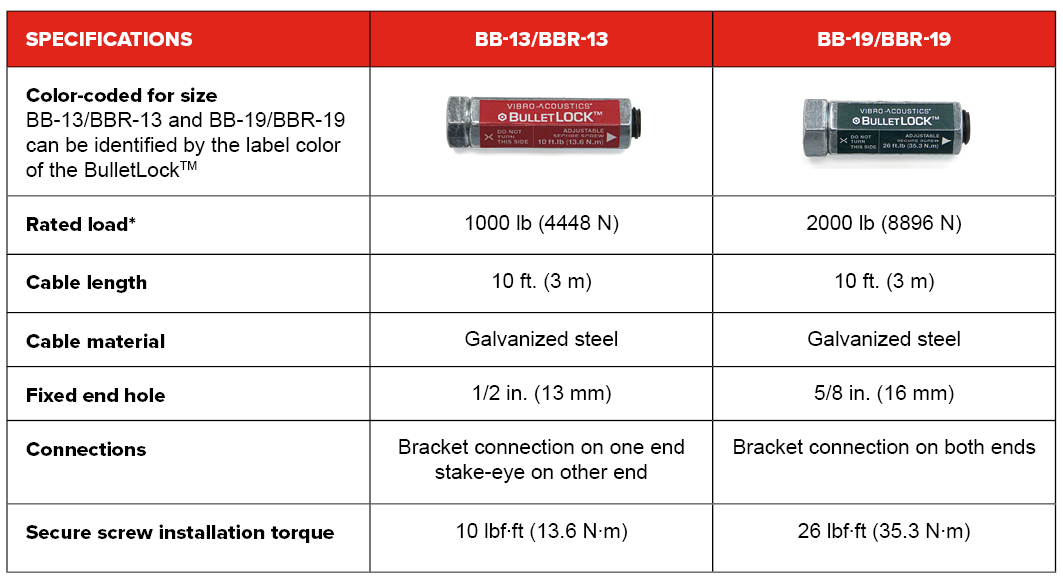

Our restraints are rated to allow for fewer, smaller restraint kits—reducing material costs. BulletBraceTM is one of the first seismic restraint kits rated for load capacities per ANSI/ASHRAE Standard 171-2017.

QUANTIFIED SAVINGS

16 min per point

*Compared to standard products

- Installing BulletBraceTM

- Installing similar products by others

Up to

time savings

INSTALLATION

Secure one end to structure. After attaching the bracket to the component, just slide and secure the cable.

Tighten the secure screw inside the BulletLockTM to the required torque.

Insert the lock screw to complete the installation.

SIGNIFICANT INSTALLATION TIME SAVINGS ON ANY PROJECT!

Project Size |

Small |

Medium |

Mid-Large |

Large |

|---|---|---|---|---|

Building Type |

School | Office or Medical Facility | Hospital | Industrial Complex |

QTY of restraints |

400 to 700 |

700 to 1500 |

1500 to 3000 |

3000 to 6000 |

Time saved per pt |

16 minutes |

|||

Total hours saved |

up to 187 hours |

up to 400 hours |

up to 800 hours |

up to 1600 hours |

*Estimated average quantities

VIBRO-ACOUSTICS’ BULLETBRACETM cable restraint system is used to restrain non-structural components against seismic, wind, and blast forces.

Typical applications include suspended equipment, ductwork, piping, and conduit. Thanks to the uniquely designed BulletLockTM cable securing mechanism, our pre-assembled BulletBraceTM kits can be secured quickly and easily.

EASE OF ADJUSTMENT

BulletBraceTM is the most easily adjustable cable restraint system in the market. The cable length can be adjusted quickly after installation to remove excess sag in the cable. For the contractor, this adjustability eliminates the need for reinstalling the cable, saving time and reducing the installer’s labor.

PRE-ASSEMBLED. JUST SLIDE AND SECURE!

BulletBraceTM comes pre-assembled. To adjust the cable, just slide and secure! This means no more fussing with thimbles, clips or brackets and no more fishing cables through holes. The result is significant labor savings.

Available in BB-13, BBR-13, BB-19 and BBR-19 versions, BulletBraceTM kits have pre-assembled ends, so they are ready for use straight out of the package.