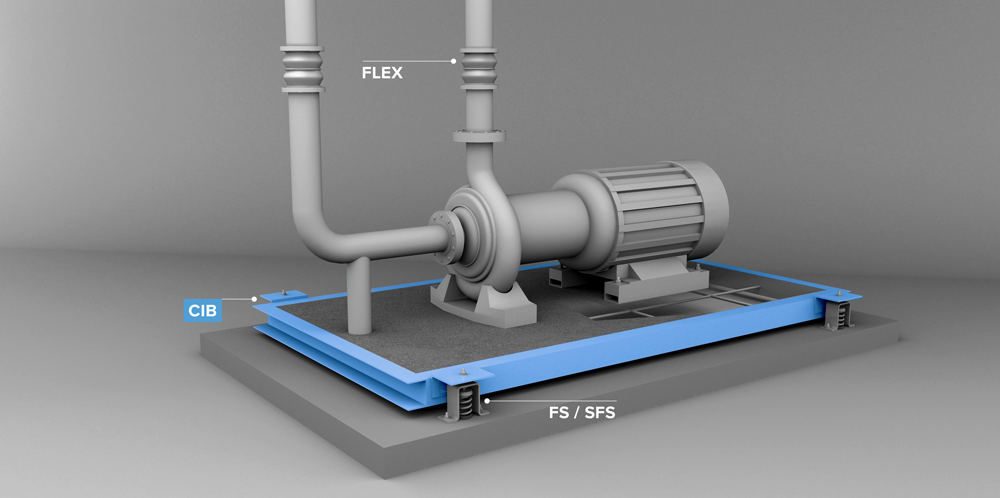

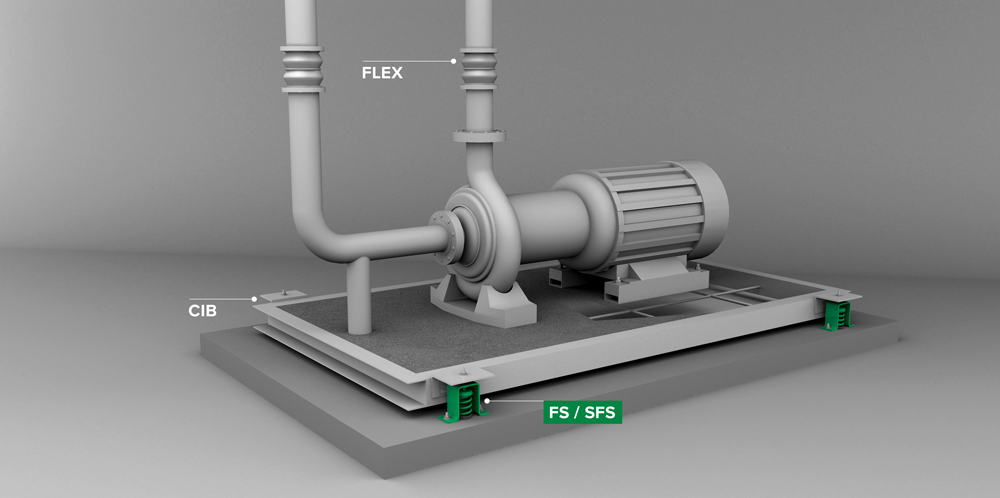

Base-mounted pumps normally require a concrete inertia base. Selection and sizing of the base should ensure that the range of motion is limited and provide the appropriate vibration isolation for the system. Housekeeping pad depth and size, exposure to extreme events, pump type, horsepower, rpm, size, location in the building, and weight distribution are contributing factors in selecting the appropriate isolators.

CIB - Concrete Inertia Bases provide vibration and start-up torque damping by adding mass to and lowering the center of gravity of the mechanical equipment it is installed under. Fans 50HP and up recommended to use Concrete Inertia Bases

SFS - Seismic Free Spring series provide vibration isolation for base mounted pumps. The isolator has a seismic restraint housing for greater lateral and vertical support.

FS - Free Spring series provide vibration isolation for base mounted that installed on floor or base. These open spring isolators compress on neoprene cups and absorb low and high frequency vibrations.

FLEX - Flex Connectors are applied to piping connections with vertical inline pumps to isolate the connecting piping and reduce structure-borne noise.

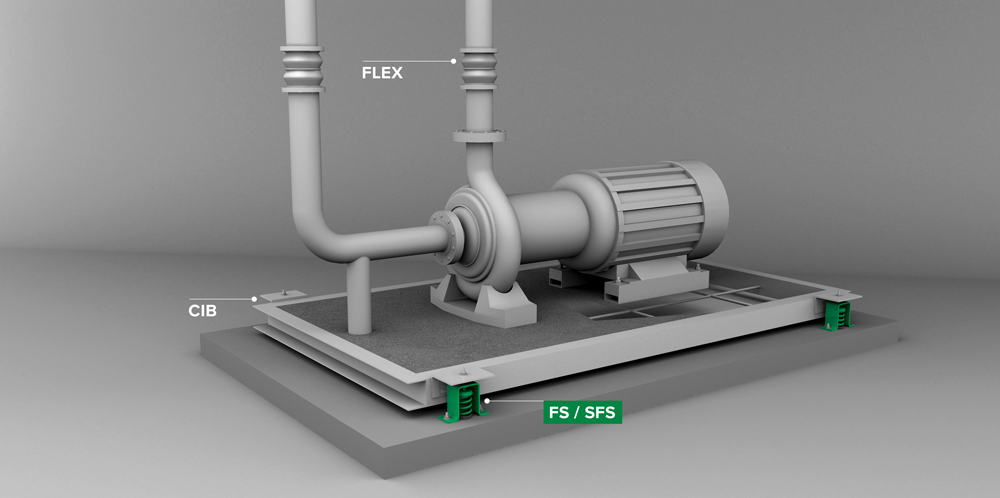

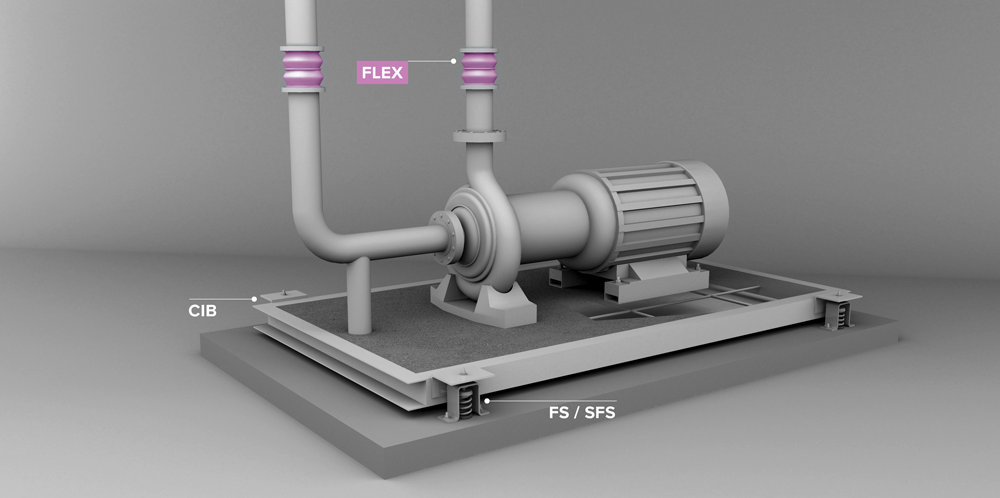

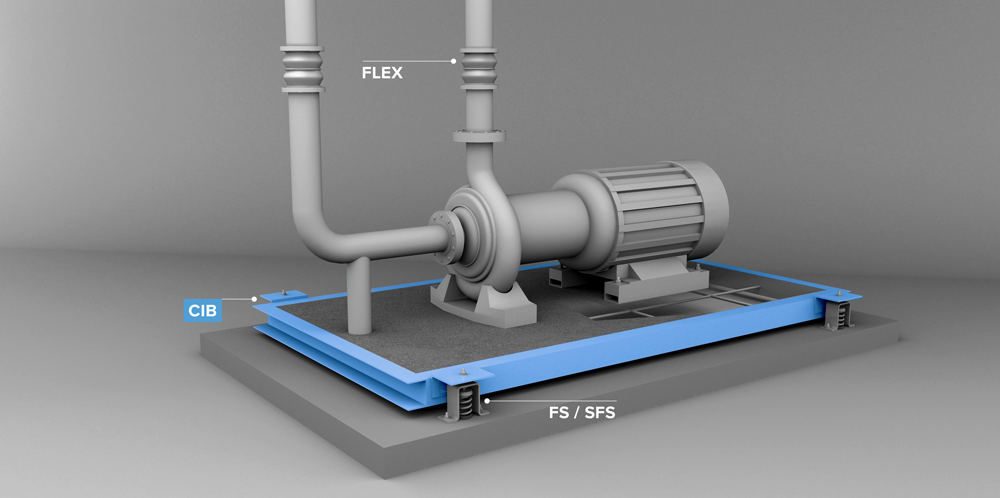

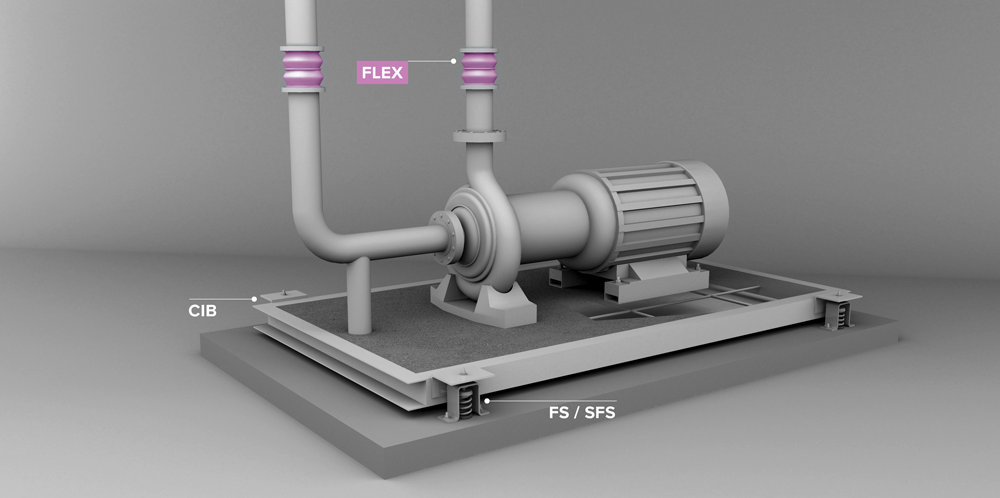

Base-mounted pumps normally require a concrete inertia base. Selection and sizing of the base should ensure that the range of motion is limited and provide the appropriate vibration isolation for the system. Housekeeping pad depth and size, exposure to extreme events, pump type, horsepower, rpm, size, location in the building, and weight distribution are contributing factors in selecting the appropriate isolators.

CIB - Concrete Inertia Bases provide vibration and start-up torque damping by adding mass to and lowering the center of gravity of the mechanical equipment it is installed under. Fans 50HP and up recommended to use Concrete Inertia Bases

SFS - Seismic Free Spring series provide vibration isolation for base mounted pumps. The isolator has a seismic restraint housing for greater lateral and vertical support.

FS - Free Spring series provide vibration isolation for base mounted that installed on floor or base. These open spring isolators compress on neoprene cups and absorb low and high frequency vibrations.

FLEX - Flex Connectors are applied to piping connections with vertical inline pumps to isolate the connecting piping and reduce structure-borne noise.

© 2020 Vibro-Acoustics by Swegon

Privacy Policy | Accessible Customer Service Policy