When it comes to vibration isolation and restraint systems at Vibro-Acoustics our goal is to save contractors time while we reduce your risk.

Did you know that labor is estimated to be 10 X the cost of isolation and restraint material and at high risk of ballooning over the project timeline?

By reducing labor you can directly impact the project margin, improve project timelines and help manage expectations. At Vibro-Acoustics we focus on delivering labor savings products and services to installing contractor to save on cost, time and headache.

The commercial construction sector, now more than ever, is struggling with workforce shortages which is why there is even more of a need for labor saving products. Our experts know that the best products minimize risk, are readily available and easy to install.

In typical seismic restraint design, the attachments to the structure are determined well after the steel structure has been erected eliminating the opportunity to coordinate their locations. Once built, the steel structure of a building is usually off limits to welding or drilling to attach brackets and fasteners. So securing non-structural components with seismic restraints in a building with a steel structure can be quite challenging.

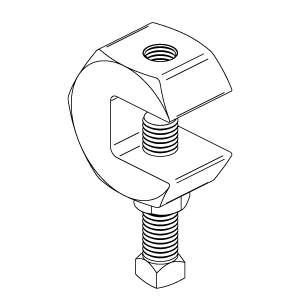

Installing a standard beam clamp may seem like the best solution for attachment of seismic restraints, but additional design modifications are typically required for standard beam clamps to make them “seismic”. And unfortunately most seismically rated beam clamps are large, bulky, difficult to handle and labor intensive.

The BulletClamp™ and its unique and simple design offers contractors a fast and easy-to install method of attaching seismic restraints to structural steel. With it’s proven 4 minute savings per clamp and one size fits all, the BulletClamp™ has been through vigorous testing and is engineered to perfection.

Keep it simple and stay safe with the BulletClamp™, learn more here.

In seismic applications, cable restraint systems provide the most common solution when it comes to restraining suspended components. But installing cable restraints can be a physically grueling exercise. They often need to be installed in hard-to-reach locations and become more of a challenge if they are non-adjustable restraint systems that use compression sleeves which require a considerable effort and large amount of space to operate the crimping tool.

Although there are some adjustable restraint systems available, most are large, complicated, come unassembled and require a significant amount of time and effort to install. But the biggest risk? Any bracing system that is difficult to install could jeopardize the project schedule with longer installation times AND higher installation costs.

The BulletBrace™ has a proven 16 minute per point cost savings and is the fastest adjustable cable restraint system that is fast, easy to use and most importantly minimizes installation time, and effort.

BulletBrace™Labor Savings:

Pre-Assembled: BulletBrace™ kits are shipped pre-assembled, a unique feature in today’s market, making them the fastest restraints to install.

Fewer restraints: Combined with the V-Anchor engineering method, BulletBrace™ restraint kits allow for designs with fewer restraint points.

Lower risk and higher accuracy on attachments to building structures: Our engineered attachment details will show attachment alternatives to help contractors make substitution decisions on-site.

Cost savings: Our restraints are rated to allow for fewer, smaller restraint kits — reducing material costs. BulletBrace™ is one of the first seismic restraint kits rated for load capacities per ANSI/ASHRAE Standard 171-2017.

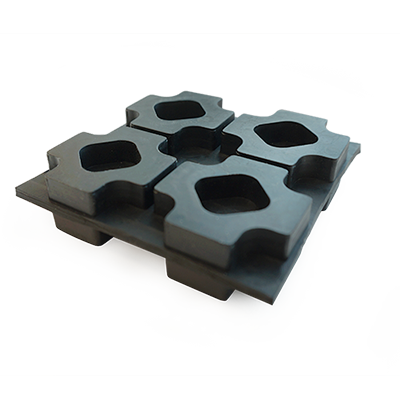

When it comes to vibration isolation pads, the most commonly available products on the market are difficult to cut or modify on site due to installation restrictions and material thickness. Plus, seismic and wind restraints designs require equipment to be bolted down-oftentimes through pad isolators- leading to risks of short-circulating the isolation or overloading the pads.

When a hole is pad in an isolation pad, it removes a certain area from the pad. This results in reduced capacity for a given pad size. The issue could be resolved by engineering the pad selection, unfortunately, this is rarely done.

Neo+ Isolation Pads are designed to perform published even when mounting anchor bolts are installed through the pads thanks to unique geometry, high strength compound and high shape factor.

The Neo+ was designed to fit most common anchor bolt sizes, anchor mounting can be done quickly by simply cutting away a thin connective diaphragm and the design can be cut to size in seconds to adjust for actual equipment weight and size.

To find more labor and cost saving vibration isolation and restraint solutions check out our full range of products and services.

Working on a project or have questions relating to vibration isolation and restraint systems? Chat with one of our Engineering Experts today: info@virbo-acoustics.com

© 2020 Vibro-Acoustics by Swegon

Privacy Policy | Accessible Customer Service Policy