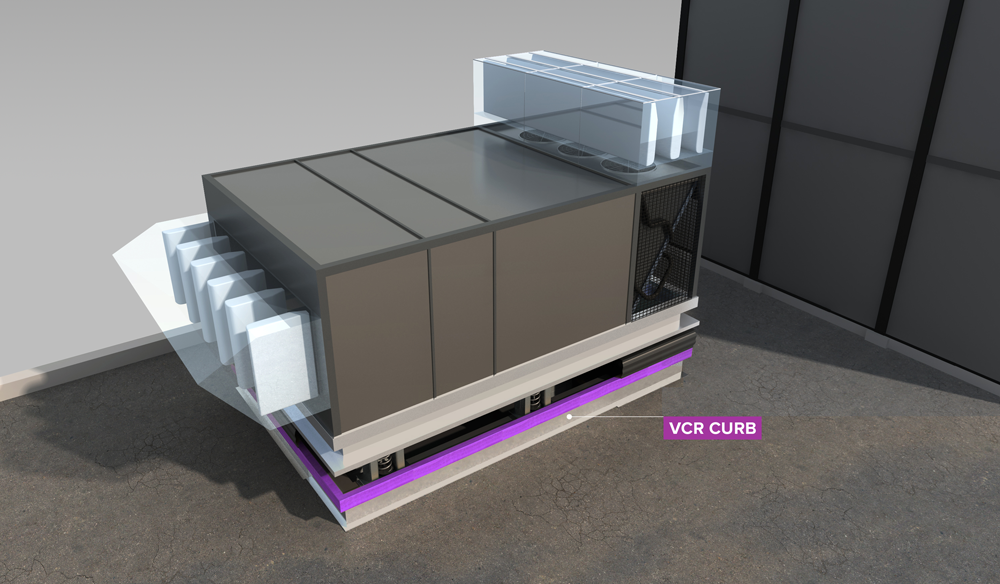

Rooftop units, primary sources of vibration problems, are often culprits of non-compliance with background sound criteria. To avert a vibration or structure-borne noise problem, engineers should specify Vibro-Acoustics' noise control curb, which provides external vibration isolation, not just isolation of the usual suspects inside the unit (fan, compressor, etc.). Rooftop units with curbs require additional calculations and bracing for extreme events to secure the two attachment planes: the unit to the curb, and the curb to structure. The Vibro-Acoustics VCR curb for extreme event applications comes with the necessary calculations, stamped by a PE/P.Eng.

VCR Curbs - Vibration Isolation Curbs series come with integral and adjustable spring vibration isolators. Galvanized steel construction with a wood nailing strip for attaching field supplied and applied flashing is standard.

VCR curbs can be constructed with a sloped bottom to match the roof pitch. As airborne noise and vibration are usually a simultaneous concern, complete systems are available incorporating vibration isolation, duct-borne noise control, radiated noise control and flexible connections.

Noise control elements are aerodynamically matched to the connections between the rooftop equipment and the ducting system to afford the lowest possible installed pressure drop and energy usage.

The Vibro-Acoustics VCR curb for extreme event applications comes with the necessary calculations, stamped by a PE/P.Eng.

© 2020 Vibro-Acoustics by Swegon

Privacy Policy | Accessible Customer Service Policy